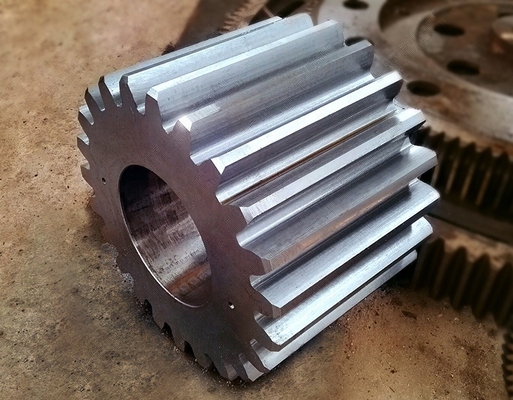

Spur gears are widely accepted as the most efficient type of gearing solution, when the application of transmitting power and

uniform rotary motion from one parallel shaft to another is required. Determined by the center distance, spur gears create a

steady functioning speed drive. This drive speed can be decreased or increased by the variable number of teeth that exist in the

driving gear.Several of our custom spur gears have been used in gear train applications - where multiple gears are required to

have the same

pressure angle and diameter pitch. They are available in plastic, non-metallic, brass, steel and cast iron. In addition ,these

parts are manufactured many style types: plain, web, web with lightening holes, and web with spokes. Many are available with or

without hubs.

Leave a Message

We will call you back soon!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters!

Please check your E-mail!

Please check your E-mail!

SUBMIT

More information facilitates better communication.

Mr.

- Mr.

- Mrs.

OK

Submitted successfully!

We will call you back soon!

OK

Leave a Message

We will call you back soon!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters!

Please check your E-mail!

Please check your E-mail!

SUBMIT